Zotsatira zamicroporous ceramic atomizing pachimakepa electronic smog

1. Porosity vs. mphamvu

Kutsutsana koyamba kwa zoumba: kuchepetsa mphamvu kumapangitsa kuti zitsulo zadothi zigwetse ufa, kumapeto kwa kugwa, msonkhanowu umakhala wogawanika, zomwe zimapangitsa kuti pakhale zokolola zochepa.

2. Pore kukula vs. mafuta conductivity

Pore kukula kwama microporous ceramicsndi yosagwirizana kwambiri mu microstructure ndipo ilibe geometry wamba.Kukula kwa pore ndi kwakukulu kapena kochepa.Kabowo ka microporous ceramics nthawi zambiri amatanthauza kugawa kwakanthawi, munjira yopitilirabe, kabowo kakang'ono ka kuchuluka kwa mafuta kumagwira ntchito yofunika kwambiri, kuchuluka kwa mafuta kumayenderana ndi lalikulu la kabowo, kabowo kokulirapo, mwachangu mafuta.

3. Kabowo vs

Kuphatikiza pa kukhudza kuchuluka kwa mafuta, kabowo ndi chizindikiro china chofunikira ndikukoma.Pamene atomizing, ngati utsi mafuta ndi lalikulu tinthu atomized, nthunzi otaya anapanga ndi coarse, ndi m'malovu anapanga pambuyo condensation ndi zazikulu, amene ali ndi mphamvu ndi zosangalatsa kukoma.Ang'onoang'ono dzenje, ndi bwino nthunzi otaya opangidwa ndi mafuta m'malovu atomization, bwino ndi aerosol particles anapanga, bwino kubalalitsidwa kwenikweni, yunifolomu, wosakhwima kukoma.Chifukwa chake, kabowo kakang'ono ka kalozera wamafuta kumakhala bwinoko.

Kusanthula mfundo zowawa zamicroporous ceramic atomizing pachimake

Katundu woyendetsa mafuta ndi mphamvu zama ceramic sizingaganizidwe, chifukwa chake pamafunika kabowo kakang'ono kuti mupeze mphamvu zokwanira zoyendetsera mafuta.Kabowo kakang'ono kamene kamapangitsa kabowo ka ceramic kuchepetsedwa;Kukoma kwa ceramic atomizing pachimake kumafuna kabowo kakang'ono kokwanira;Mphamvu za Ceramic, ma conduction amafuta, zokonda zokomera pobowo ndizosiyana ndendende.Ceramics muzinthu zitatu izi za ntchitoyo sangathe kupereka chidwi kwa onse awiri, ndizotsutsana.Koma pachimake cha ceramic atomization pachimake, kuphatikizapo mpikisano waukulu wa ndudu za e-fodya ndi kukoma, komwe ndi ntchito yomwe iyenera kutsimikiziridwa poyamba.Choncho, pore kukula kwake ndi kochepa kwambiri kuti apereke mafuta okwanira.

1. Kukula bwino kwa pore komanso kutsekemera kwambiri:

Nano ceramic chuma kukonzekera luso, kulamulira tinthu kukula ndi ndende ya ufa ceramic, kupeza bwino pore kapangidwe ndi anaikira pore kugawa kukula, kupewa kutaya mphamvu chifukwa cha pores lalikulu.Konzani kuchulukana kofanana kwa ufa wa ceramic, onjezerani pore-kupanga mlingo, ndi kukwaniritsa porosity mkulu

2. Kuwala kwama microporous ceramics:

Sinthani chilinganizo zakuthupi, sinthani mphamvu yamkati ya zida za ceramic, kupanga molondola ndikuwongolera kutentha kwa sintering, kupeza digiri yabwino ya sintering, kuti mukwaniritse bwino pakati pa porosity ndi mphamvu.Mapangidwe olondola a mafakitale adzakwaniritsa bwino pakati pa mphamvu, porosity ndi kabowo, kuti akwaniritse kuwongolera kwamafuta ndi kukoma kwake.

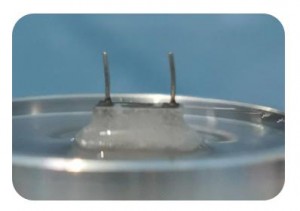

3. Chinthu chinanso chowawa cha pachimake cha ceramic ndi kutuluka kwa chikonga ndi essence mu mafuta a ndudu.Imafunika malo okhazikika a kutentha, ndipo kugawa kwa kutentha sikuli kofanana.Kuti tikwaniritse kukoma komaliza, kutentha kwa waya kumafunika kuti pakhale bwino komanso kusintha mwamakonda, kotero kuti chitukuko chamakono cha microporous ceramic atomization pachimake ndichopanga zitsulo zosinthidwa pazitsulo za ceramic.Pali njira zambiri zopangira zitsulo za ceramic pamalo, ndipo imodzi mwamaukadaulo omwe amagwiritsidwa ntchito kwambiri pafodya ya e-fodya ndi kusindikiza kwa filimu yokhuthala, yofanana ndi PCB burashi solder phala.Izi sizimangochitika pamalo athyathyathya, komanso pazithunzi za 3D.

Nthawi yotumiza: Jul-19-2022